Save on fuel, dollars, emissions and noise by pairing your generator with one of our mobile battery solutions.

Pairing one of our battery solutions with a diesel generator is one of the easiest, quickest and most cost-effective ways to cut down emissions by as much as 75%, while also driving significant efficiencies and cost savings.

These include:

- Fuel and maintenance savings – by pairing with our batteries, you can dramatically reduce genset run-times which can cut fuel usage and costs by over 50% and extend maintenance intervals from weeks to months

- Reduce fuel handling and storage – less fuel usage means less fuel movements, reducing risk and hassle on-site, as well as cutting down fuel transport and handling costs

- Cut down noise on-site – with the battery providing silent power for majority of the time, the noisy genset is needed for far less time and can charge up the battery in short, efficient bursts

- Bolster productivity – the battery provides continuous and reliable power mitigating the risk of down-time from power outages and brownouts, and supports both short-term, high-power peaks and long-term energy reserves

- Optimise your genset and save – pairing with our battery can reduce genset oversizing, eliminating long periods of idling, protect against wet-stacking and remove inefficiencies and wastage in fuel, emissions and dollars

How does it work?

Pairing a diesel generator with a battery is a highly practical and efficient way to not only drive decarbonisation, but also to cut down costs – and it works.

This hybrid set-up has been deployed and proven all over the world time and again, with savings on fuel and emissions of anywhere between 50-85% – not to mention the additional benefits of less noise, reduced fuel handling and storage, increased productivity due to decreased down-time, reduced genset maintenance costs and more.

With Powershift, you have the added benefit of accessing one of our mobile batteries under a flexible hire arrangement – meaning no CAPEX outlays and a full service and support model that includes analysis by our team on the best set-up for your generator to optimise the outcome. When your project or use case is over, you return the battery to us just as you’d return your rental generator – or you take us to your next project.

So how does it actually work?

By pairing a mobile battery system with a generator, the battery takes over and essentially becomes the ‘brains’ of the operation, switching the generator on only when the battery needs charge, and auto turning it off when it’s no longer needed. All of our mobile battery systems have advanced control systems that can be programmed to work alongside any diesel generator and can also be configured with automatic timers and other advanced settings to suit your unique requirements.

Generator + Battery: How they work together

1. Generator charges the battery while the battery simultaneously supplies power to the load

2. When the battery is fully charged, the generator is auto-switched OFF and the battery continues to provide silent, clean power to the load

3. When the battery is almost depleted, its software auto-restarts the generator

In this hybrid genset + battery set-up, we can reduce the generator run-times significantly – anywhere between 50-85%, depending on the application and the load the generator is powering. This directly correlates to reducing fuel usage and subsequently CO2 emissions.

As an example, the image below shows our LX60/125 unit paired with a generator to power an industrial construction site. In this example, the generator went from running 24/7, to running for approximately only 3 hours to recharge the battery. For the remaining 21 hours of the day, the battery was powering the load from its stored capacity. This resulted in significant fuel, cost and emissions savings – see below for highlights and read the Case Study here.

LX60/125 paired with genset to power industrial construction site.

RESULTS

- 24/7 generator down to 21 hours on battery, 3 hours on generator per day to recharge battery

- Reduced operational costs due to reductions in fuel and maintenance

- Over 88 tonnes of CO2 saved over a 6 month period

Unpacking the benefits in more detail

A battery + genset set-up allows the generator to run at its most optimal load – reducing down-time, maintenance and wastage in fuel, emissions and ultimately, dollars.

Generators are designed to run above a minimum output load, ideally operating at around 30-80% of their maximum capacity as a general rule of thumb. This band is where they operate most effectively and where fuel consumption is also at its most efficient. When a generator operates below this band frequently or is idling for long periods of time – for example when the load it’s powering has peaks and troughs – it’s not only inefficient, it damages the generator.

This leads to issues with generators failing prematurely, interrupted or unreliable supply of power, increased maintenance costs, and shortened life cycles of the generators.

When a generator is paired with a battery, it kicks in only to charge the battery, which is a constant, continuous load, allowing it to run at peak efficiency for the few hours it’s needed to complete the recharge. Once recharge is completed, by auto-switching off, you eliminate idling and wasteful running hours.

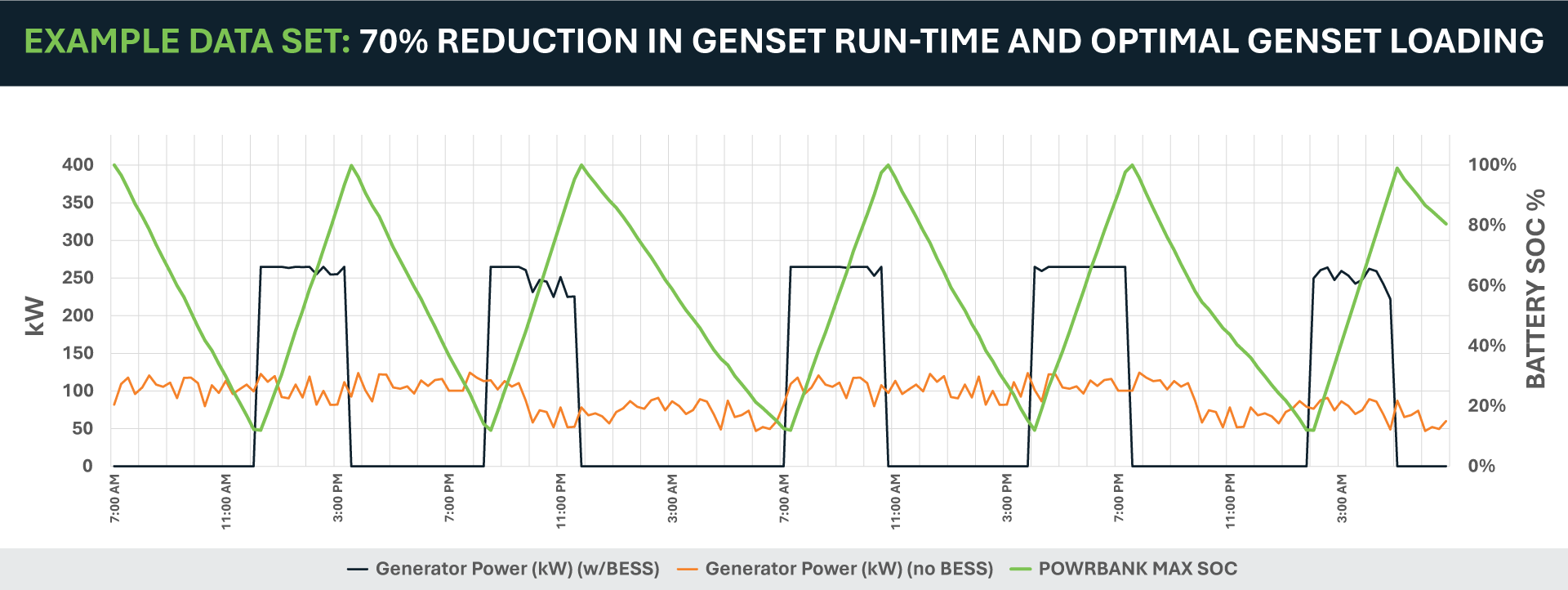

Example Data Set: 70% Reduction in Genset Run-Time and Optimal Genset Loading

Running the generator at peak efficiency and for less time ultimately leads to substantial cost savings in both fuel consumption and maintenance costs.

It also means that the genset is running how it’s designed to be run, reducing the risk of down-time from power outages and brownouts. The battery manages this safely and efficiently, providing continuous and reliable power and making sure productivity across site is maintained.

Efficiency gains mean the genset can often be downsized, cutting costs and saving on fuel

Generators are often oversized for the job, especially if they’re running a load that has peaks and troughs. This is because they need to be sized for the highest peak, plus an additional safety margin on top, even if that peak is only going to be hit once or a few times in a day. The rest of the time, the genset is often underloaded and running incredibly inefficiently.

By adding a battery into the mix, it can manage the peaks efficiently and often leads to the opportunity to downsize the generator to a smaller, more cost-effective unit, saving on both running and rental costs.

The example below shows our POWRBANK MAX unit paired with a generator to power a range of construction equipment at a large data centre building site. In this case, a 400kVA generator was able to be downsized to a 250kVA generator and run for only 4 hours per day a to recharge the battery, saving on fuel consumption, rental cost of the generator and genset maintenance costs.

POWRBANK MAX paired with genset to power construction of a data centre.

RESULTS

- Original requirement was a 400kVA generator, downsized to a 250kVA to recharge batter only

- Ran for only 4 hours per day compared to 24/7

- Dramatically reduced fuel consumption and genset service frequency

Less fuel means less fuel handling – reducing risk and hassle

In some cases, reducing fuel movements and the regularity of fuel handling is as critical as reducing the cost of refuelling – especially where access to site is logistically challenging and/or where safety hazards are heightened. Consider remote locations like islands, sites where road access for refuelling is challenging, or where the capacity for storage and handling of excess fuel is limited or unsafe.

The less frequently you need to refuel and less you need to store and handle on site, the more you can reduce risk, hassle and save on additional fuel transport costs.

Less genset run-time means less noise – increasing health, wellbeing, safety and the ability to operate overnight

This one is obvious, but crucial for some operations where noise is a major issue – consider residential environments, overnight operations, events, filming, and work sites where constant noise pollution is detrimental to health, wellbeing, and safety.

For the construction and utilities industries in particular, where works are often occurring in amongst working businesses and homes, any reductions in noise that be achieved through reducing the generator run-time are critical. This not only keeps the community happy, but also allows for overnight works to be completed with minimal noise through managing and staging when the battery runs versus when the generator is set to recharge the battery.