Boost any limited grid supply with additional clean, quiet power that handles peaks AND give you more capacity to power through the day

Limited grid supply is a major issue impacting businesses across every industry – whether you’re a construction site with not enough supply to power heavy machinery and equipment, a manufacturing business looking to grow and ramp up operations, or a farm with seasonal peaks.

So what do you do when you need more power than your grid connection can supply?

- If your need for more power is permanent or ongoing – you’ll likely apply to your Distribution Network Service Provider for an upgrade. Due to grid constraints, if your application is accepted, wait times for upgrades can be anywhere from 6-18 months.

- If your need for more power is temporary, either due to waiting for a permanent upgrade or it being a time-bound / project-based need like a new build – you’ll likely seek out a generator for the job. While the genset itself might not be too costly, the fuel and maintenance costs will be.

Where does a mobile battery solution fit in?

Historically, options for anything outside a diesel generator in this scenario have been extremely limited. If a battery entered the conversation, it would have either been a fixed solution, requiring a high CAPEX investment for what is only a temporary need; or a smaller mobile battery that would struggle to meet the required power and capacity demands.

Mobile battery solutions like the extensive range we have in our fleet can cover all bases, and through Powershift’s flexible hire model, they’re perfectly suited to alleviate temporary grid supply constraints, providing additional power and capacity when and where it’s needed.

Through leveraging powerful and versatile Mobile BESS products like those in our fleet, we can:

- Easily meet max power needs – with units offering peak power that varies from 150A all the way through to 750A. Some also have the ability to parallel (or join) units, which all you to double that peak power.

- Draw on very limited grid supply – the majority of construction sites have access to very limited temporary supply, usually 80A or less. With units in our fleet built specifically to power big peaks from limited supply, we can often support multiple pieces of equipment such as cranes, hoists, jump forms, site power and concrete pumps from between 16A-80A. The units most typically remain on ‘trickle charge’ and have the ability to very quickly ‘top up’ in between peaks.

- Eliminate the need for a diesel generator – with the battery supplying the power and capacity you need with only a minimal grid connection to charge, there’s no longer a need for a generator.

- Optimise an existing generator if no grid supply is available – in off-grid scenarios, batteries can pair with the generator and act as a load buffer, absorbing the large demand peaks. This is not only more efficient, but can also allow for the genset to be downsized to a smaller, more cost-effective unit.

- Provide temporary back-up if site power goes down – depending on the battery unit being used, you have the ability to draw on stored capacity as a temporary back-up if grid or generator input is lost, giving the site time to resolve the issue without a loss of power.

SOLUTION COMPARISON

GENERATOR ONLY

GENERATOR + BATTERY

Oversized genset for the job

Manage peaks efficiently and downsize the generator to a smaller, more cost-effective unit

Runs all day at mostly low and inefficient loads, which is bad for the genset, the environment and your pocket

Leverage the genset in efficient optimal bursts, reducing genset run-time, fuel usage and emissions

ELIMINATE GENERATOR – BATTERY + GRID

Battery powers the load while trickle-charging from minimal grid supply.

How this works in practice

Leveraging A MOBILE BESS to

run large on-site crane and hoist.

Scenario 1: Use a Generator Only for the job

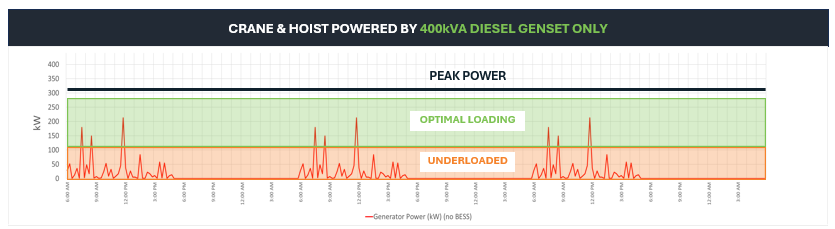

The below shows real data of crane and a hoist on a construction site being powered by a standalone 400kVA generator.

GENERATOR ONLY

- Genset run time 11hrs / day

- Diesel fuel ~235L / day

- Genset oversized for the job therefore is underloaded for 96% of runtime, highly inefficient and also at risk of premature failure

In this example you can see the generator is grossly underloaded and inefficient, running at its optimal rate for only 4% of the 11 hours a day it’s operating.

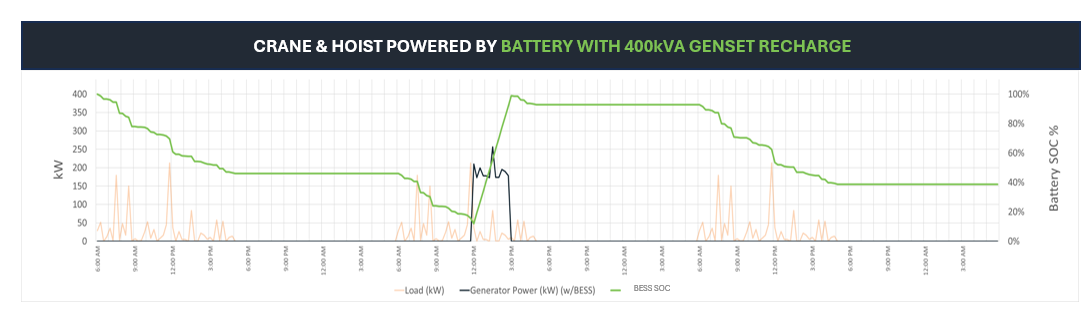

Scenario 2: Add a Mobile BESS, paired with the Generator

This second graph shows how the Mobile BESS battery (green line) is now powering the crane and hoist for the day, with the generator (dark blue line) only kicking in for approx. 3 hours to re-charge the battery .

GENERATOR + BATTERY

- Genset runtime reduced by 85%

- Diesel fuel reduced by 68%

- CO2 emissions reduced by 68%

- Genset is correctly loaded

- Genset could be downgraded to 150kVA unit for further savings.

This solution reduces generator run-time by 85% and cuts fuel consumption and emissions by 68%, while also optimising genset operations.

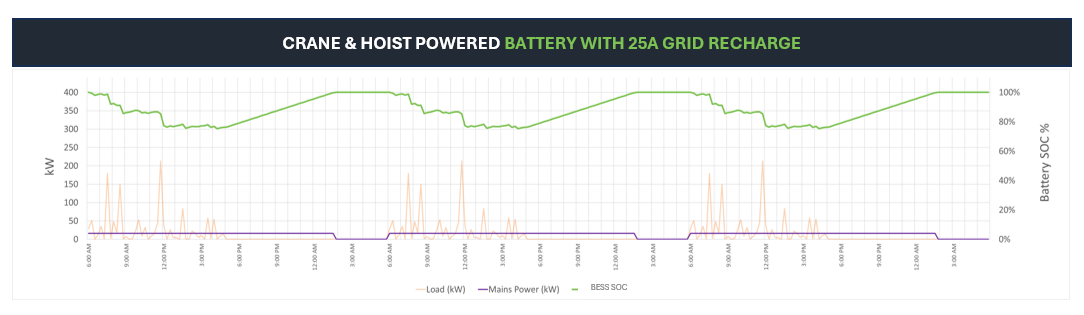

Scenario 3: Eliminate the Generator – Use a Mobile BESS on a 25A Grid trickle charge

This third graph shows how with a small 25A grid supply, the battery can meet the power peaks required by the crane and hoist while on trickle charge (i.e. continuous charge at low rate), eliminating the need for a generator.

GRID + BATTERY

- Genset eliminated

- Diesel fuel eliminated

- Noise and inefficiency eliminated

- Flexibility to charge out of business hours to preserve daytime site power

- CO2 emissions reduced by 75%

This solution provides the optimal outcome – removing the generator, fuel, emissions and noise, and providing a continuous, reliable power supply that can easily meet the site’s needs.

Having the right tool for the job is essential. Mobile BESS systems are a convenient, efficient and cost-effective option for sites with limited grid supply.

Not sure where to start? Take a look at our product range along with some of our case studies to learn more or reach out to our expert team for specific advice on your project.