The basics – Batteries, BESS and Mobile BESS

Most of us have a basic understanding of what a battery is – at its simplest level, it’s something that stores electrical energy which can conveniently be used at a later time. Batteries are central to our everyday modern life – they’re in our smartphones, our computers, and are core components to fast-evolving technologies like Electric Vehicles for example.

A Battery Energy Storage System, or “BESS”, is a packaged system that includes batteries inside it, along with a collection of other equipment and devices – like invertors and computers – that work together to charge, store, convert and discharge power across a range of sources and applications when it’s needed.

Traditionally, BESS solutions have all been ‘fixed’ i.e. stationary solutions that are built and assembled at a particular location and remain there permanently to store and release electricity.

In more recent years, innovations in this technology have enabled the introduction of Mobile BESS.

Unlike traditional fixed BESS solutions, these Mobile BESS are capable of being moved around flexibly, quickly and easily to different locations, making them a game-changing solution for industries that need the ability to either move their power as they move, or that need a temporary power solution on a project or seasonal basis.

Key components of a Mobile BESS – a smart battery in a box

Like any product – not all Mobile BESS systems are alike. There are variations across a number of parameters including:

- Size – both physically, and in power (kW) and capacity (kWh)

- Battery chemistry and energy density

- Quality of the internal system components and the outer container

- Heating and cooling systems and the external temperatures they can operate within

- Fire safety systems

- Software that controls the system and its functionalities

Below we illustrate some of the core components in Mobile BESS systems.

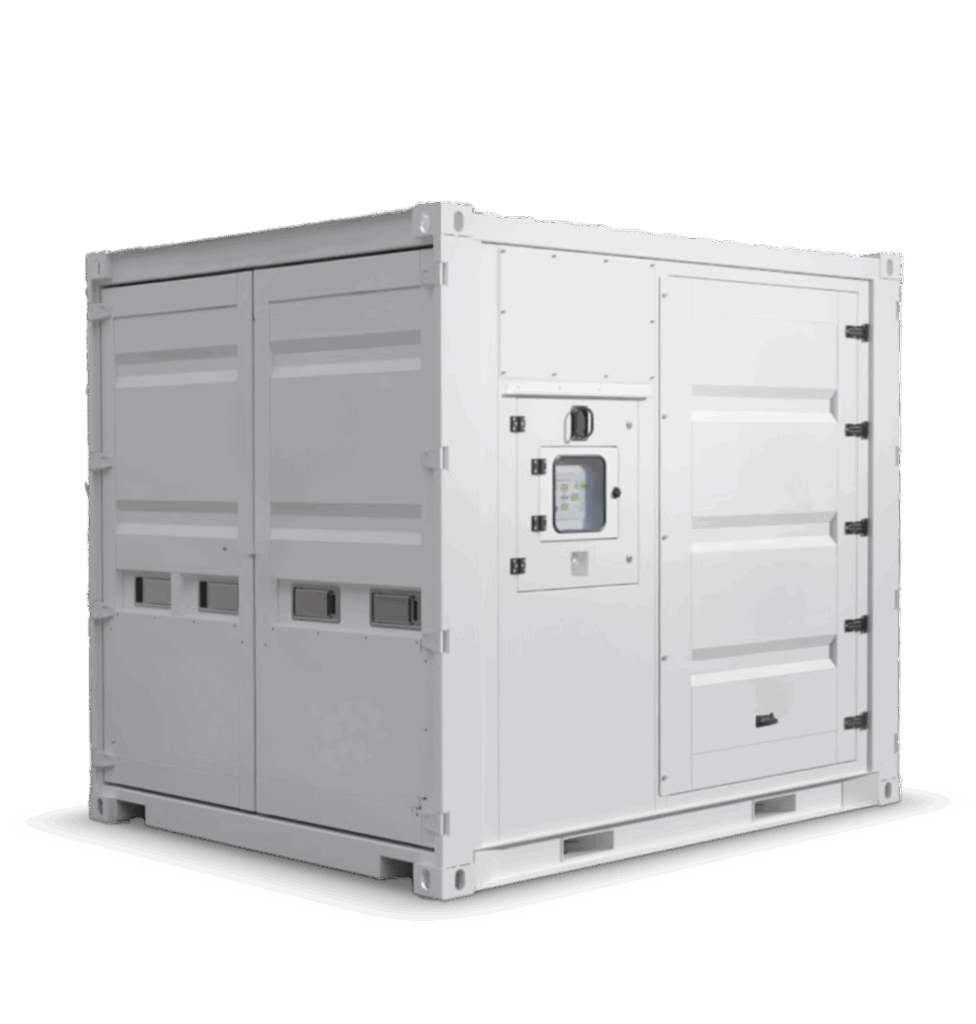

The outer container / canopy – what the system is ‘packaged’ in

The outer container of a mobile battery is what the system is housed in and what is exposed to the elements. Given mobile batteries are used in all kinds of environments with variations in weather conditions and terrains, the more robust the container, the more likely it can withstand harsh environments and be able to support a wide range of applications.

Our Mobile BESS products are all housed in high quality, ruggedised canopies, from pallet-sized stainless steel through to 10ft sized marinised shipping containers. The quality of the casing and its IP rating help to protect against dust and water getting into the system, which is vital when deploying assets into harsh environments.

Different shapes and sizes have benefits in different environments. Modularised containers make transported and relocation easily. Some smaller units are ideal for space-constrained sites like urban construction site, whereas larger assets may suit both larger projects, as well as more ruggedised or remote settings.

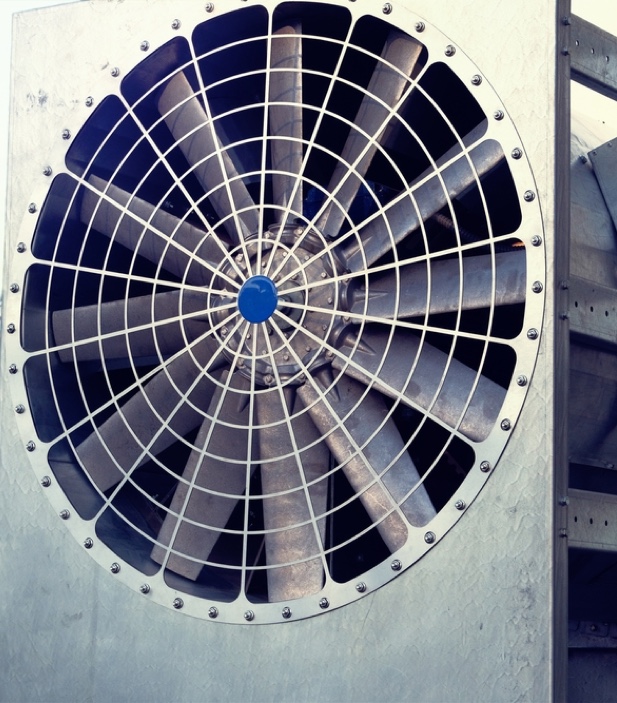

Cooling and Heating / Operating Temperature Control

Not all Mobile BESS systems have active heating and cooling systems installed – from our perspective, this is an essential feature, especially in harsh and hot climates like Australia. It ensures that all devices inside the container are maintained within their optimal operating temperature range, which means that they will not only work as they’re meant to – but most importantly, it adds an additional layer of system safety.

There are different temperature control technologies used in different systems. The majority of our fleet have HVAC (Heating, Ventilation and Air Conditioning) systems installed, which keep the internal systems at an optimal temperature of about 25°C. Some also leverage liquid cooling, which can be even more effective in hot and humid climates.

Mobile BESS systems also have different temperature ratings, which is a factor of the battery cell technology, the canopy, insulation and heating/cooling systems. Our products range from -20°C up to +50°C. In Australia, temperatures can regularly reach above +40°C, and cooling systems can only do so much if this is sustained over long periods, therefore choosing the right product for the job is essential.

The Batteries

Inside every Mobile BESS are the batteries themselves. These are the heart of the storage system and vary from system to system in size, weight, chemistry and efficiency. All of our systems use a variant of Lithium-Ion technology, most typically high density Lithium-Iron-Phosphate batteries. Each battery cell is arranged into modules, and subsequently into racks that are installed into the container.

The batteries are the DC (Direct Current) storage mechanism of the system. The majority of our fleet can also be charged from multiple sources including renewables like solar, from the grid, and from diesel generators – or a combination of sources simultaneously.

Often, we have customers that have multiple charging sources, like a small supply from the grid and a solar PV system for example. In this instance, more capable Mobile BESS systems are capable of prioritising solar as the primary input so that they take the cleanest source of energy first to charge up, with the remaining coming from the grid, which is also beneficial to the customer in managing electricity costs. The batteries store this energy and can either discharge or offload it at the same time into whatever the battery is powering – or because the system is fully mobile, it can charge up and then be moved fully charged to another location where the power is needed.

This is the beauty of a truly mobile solution – power when and where you need it.

Different systems have different numbers and arrangements of batteries inside them. This dictates their output power (kW) i.e. how much power can be delivered at a single point in time, and their capacity (kWh) i.e. how much power can be delivered over time.

Whether you need more peak power (kW / A / kVA), or more capacity (kWh), or both, depends on what you are powering. We focus on having a versatile fleet that can cater to all requirements. The beauty of how Mobile BESS have evolved over time is that there are many variations available. Browse our product range to learn more about the different variations.

The Inverter or Power Conversion System (PCS)

The inverter inside a Mobile BESS is responsible for converting electricity from DC (Direct Current) to AC (Alternating Current). Some more sophisticated Mobile BESS solutions have a Power Conversation System (PCS), which allows for this action to be bi-directional i.e. it can convert from DC to AC and the other way around.

You might have a scenario for example, where electricity is coming into the battery from a diesel generator or the grid, which is delivered as AC. The PCS will convert this into DC so that it can be stored in the batteries, and then back to AC so that it can deliver the electricity in a format that can be used by whatever you’re trying to power – like a crane or a pump for example.

All of our units use high quality, industrial-grade PCS’s. The diversity of our range means that we can meet power requirements from under 150A through to over 750A, covering a multitude of commercial-industrial applications.

The control system – the brains of the operation

The control system is located inside the Mobile BESS and is essentially the ‘brains’ of the system. Every Mobile BESS will have some form of control system as this is essential to being able to operate the unit, though many are third-party ‘off-the-shelf’ solutions. The quality of the control system, the software, and its functionality are key to differentiating what different Mobile BESS are able to do and also what they can record in terms of data – an essential asset for any user of a BESS solution.

How capable the control system is will dictate the complexity of functions a Mobile BESS can perform. It enables an operator to perform a wide range of functions from powering the system on and off, to setting timers for the battery and/or connected assets like a generator to automatically turn on and off, to reading data on energy usage and system performance.

Control systems are also typically coupled with a cloud-based platform that is accessible remotely, 24/7. This enables anyone with access, the ability to both monitor and control the unit’s operation from anywhere, as well as to read data and generate reports including energy usage over time, and savings on CO2 emissions and fuel usage for example. This type of data gathering is invaluable to users of Mobile BESS that are looking to optimise energy usage, implement proactive energy management strategies, and report on key ESG metrics, for example.

An important takeaway – the more advanced the software is, the more capable the Mobile BESS’ functionality is and the more power you have as a customer to leverage the battery and its data.

Fire safety system

Lithium batteries have become synonymous in people’s minds with fires. There’s no doubt that Lithium batteries are hazardous, in the same way fuel and other ‘dangerous goods’ are that you would find on many industrial sites. Like any hazardous item, the key is to have rigorous fire safety standards and protocols in place.

Unfortunately, in the BESS and Mobile BESS space, there are still systems in the market that either don’t have any fire protections in-built, or if they do, they’re suboptimal. From our perspective, fire safety is a non-negotiable and is a critical component of any Mobile BESS.

All of our units have multiple layers of fire safety mechanisms in-built and meets a number of internationally recognised fire safety standards. The systems monitors battery health at a battery cell level, which allows for early warning via alerts, as well as isolation of any issues before they spread to other cells. If for any reason there is a spread, the system has multiple smoke and heat detectors, along with in-built aerosol-based fire suppression technology, which is fast acting and also prevents re-ignition.

These elements, together with a high-quality designed and engineered product that is safe to operate and to move, and that complies with the latest international and local standards, are critical, and what sets Mobile BESS systems apart.